HSR AG develops and sells complete controller systems that can be integrated into the customer’s control system with just one selectable interface. The control software is directly embedded in the microcontroller, ensuring smooth operation without the need for maintenance.

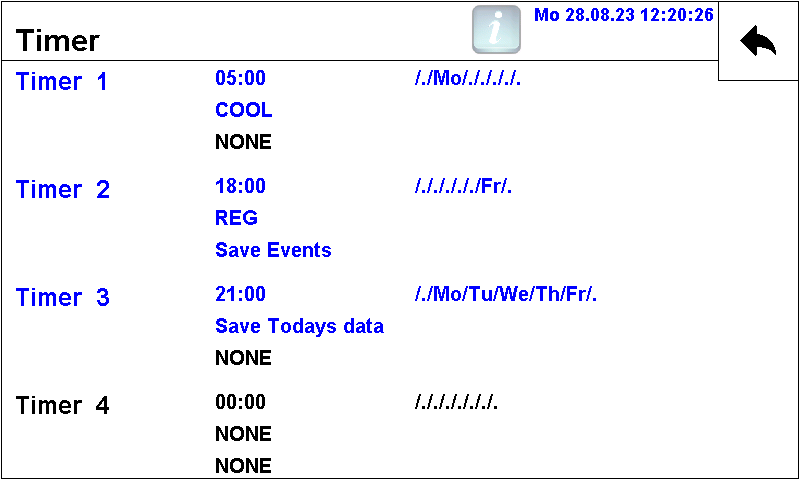

HSR controllers ensure fully automatic and error-free operation as well as monitoring of all important operating states.

With the specially developed H-Bus, communication between the controller and connected components is greatly simplified. For example, temperature and pressure transmitters signals can be read directly on the pump and sent to the controller via the H-Bus. Compressors and heaters can also be controlled via the H-Bus.

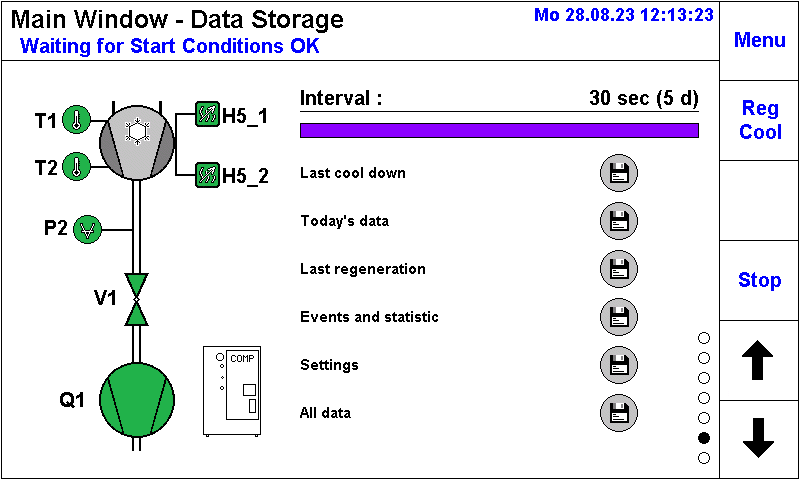

HCC 200 / HCC 220

HSR controller for independent operation or integration into the plant control system.

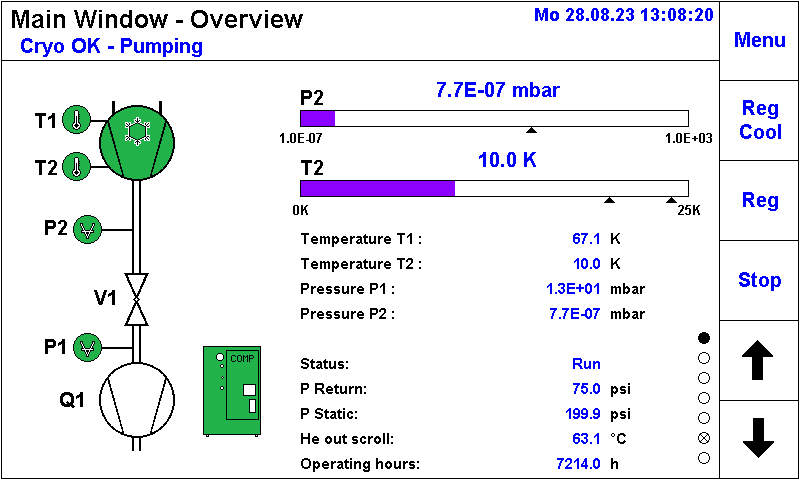

- Touchscreen operation

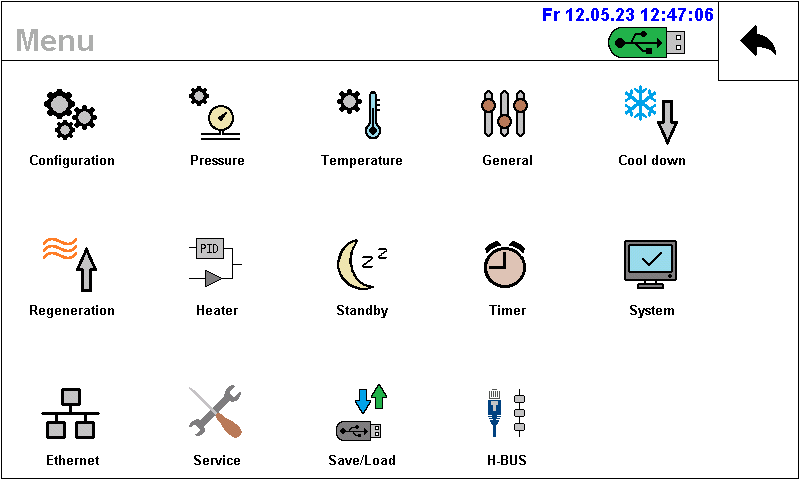

- Menu-guided configuration

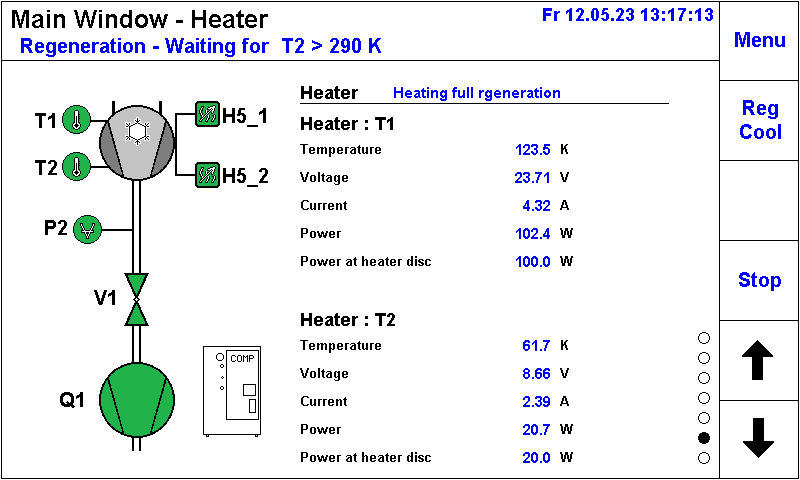

- Display of temperatures for 1st and 2nd cold head stages

- Possible to connect vacuum gauge heads from all commonly known manufacturers and of all types

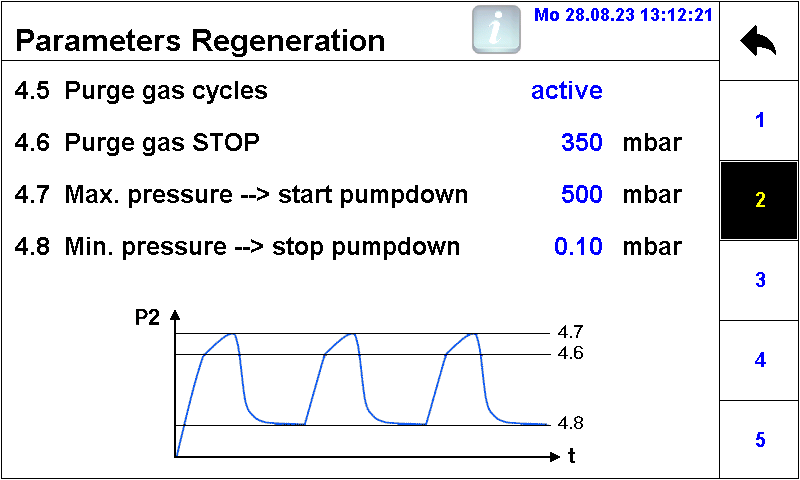

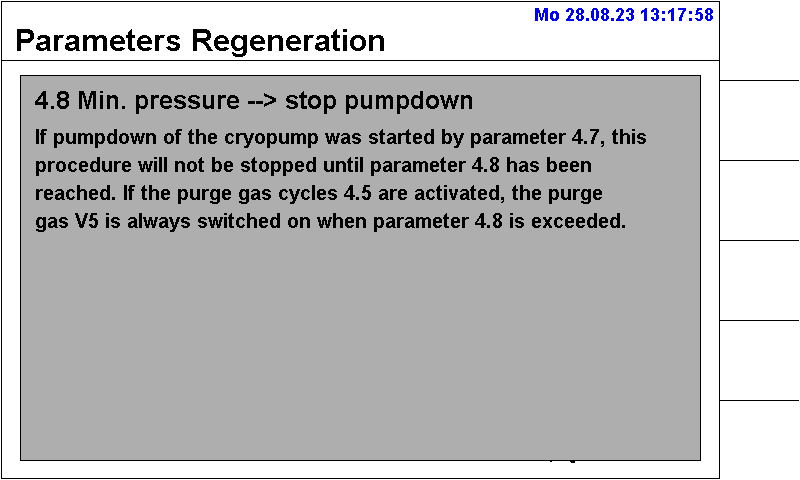

- Fully-automatic cooling and regeneration sequences

- 6 different regeneration sequences freely selectable and configurable

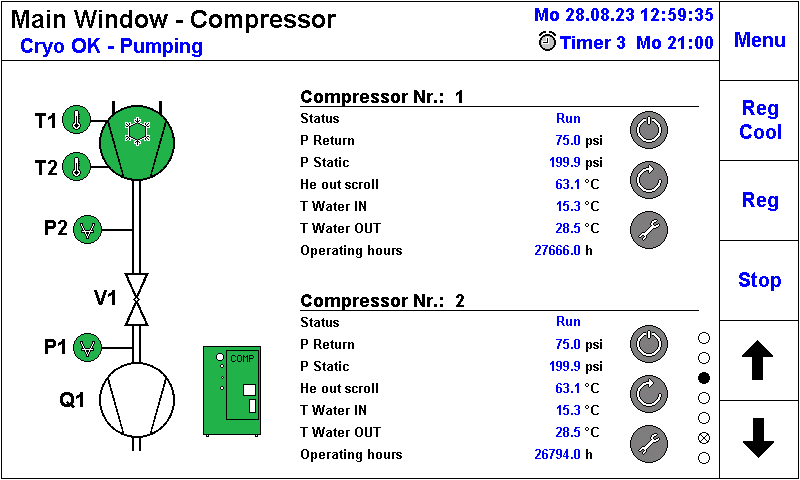

- Control of all attachments and components for operation (helium compressor, heaters, forevacuum pump, forevacuum valve)

- Interface for customer control via RS-232, Ethernet, or digital input/output

- Internal datalogging

- Stored event, statistical, and measurement data can be read via USB stick or Ethernet

- For each controller, up to 12 temperature sensors can be read out and a maximum of 15 compressors can be controlled via the H-bus

- Temperature sensors (1st and 2nd cold head stages)

- Pressure gauge heads (pumping pressure and forevacuum pressure)

- RS-232

- Analog IN/OUT (D-SUB)

- Digital IN/OUT (D-SUB)

- Compressor (D-SUB)

- Ethernet

- H-Bus loop

CBO 200 / CBO 201

With this box, the connections for digital and analog signals, as well as the power supply for the heater, are outsourced to the pumps. The box communicates with the HCC controller via the H-bus.

- Forevacuum pump

- Forevacuum valve

- Temperature sensors (1st and 2nd cold head stages)

- Pressure gauge heads (pumping pressure and forevacuum pressure)

- Purge gas heater

- Heating jacket

- Heating cartridge

- H-Bus loop

CBO 050

This standalone controller features a PID regulator with phase-cut control for precise temperature regulation of the first stage. The heating cartridge is used for this purpose. This controller is used for operating cryostats or sputtering pumps. Up to 15 CBO 050 boxes can be looped via the H-bus and monitored with the HSC 200. In standalone operation, the control parameters can be adjusted via the RS-232 interface.

- Heating cartridge

- Temperature sensors (1st and 2nd cold head stages)

- RS-232

- H-Bus loop

PUR 250

The DC power supply PUR 250 is required for operation of the HSR cold head heaters. The box is mounted in the rack next to the HCC controller.

- Cold heat heater

- H-Bus loop

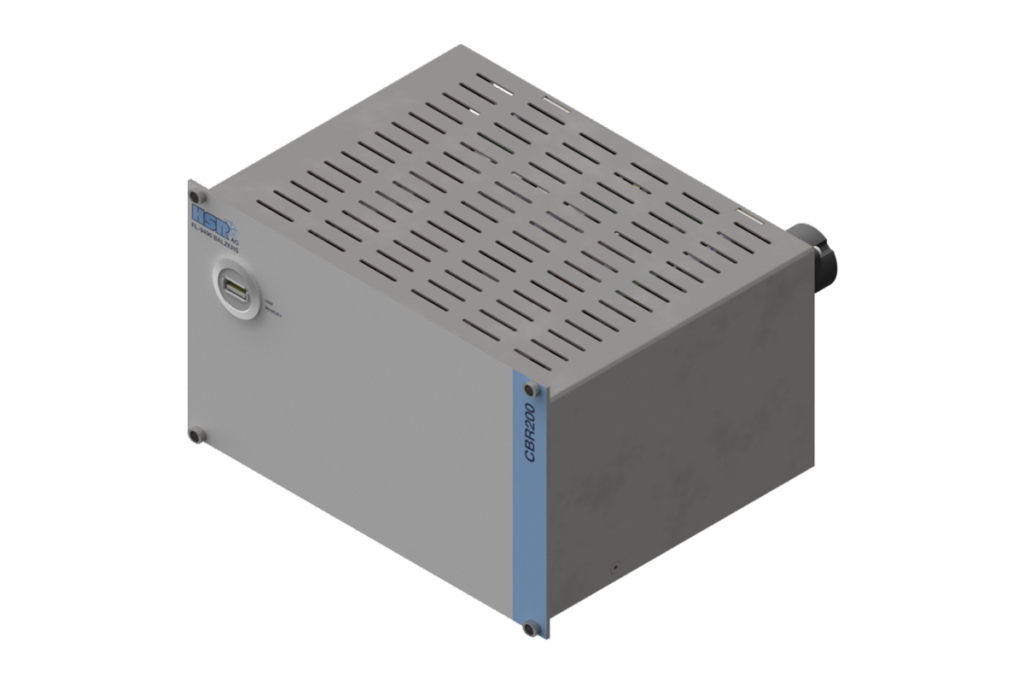

CBR 200

The CBR 200 is the rack-based version of the CBO 200/201. It is installed in a 19″ rack next to an HCC 200 or HCC 220. Additionally, the CBR 200 is equipped with a phase-cut control, enabling precise temperature regulation of the 1st stage.

- Forevacuum pump

- Forevacuum valve

- Temperature sensors (1st and 2nd cold head stages)

- Pressure gauge heads (pumping pressure and forevacuum pressure)

- Purge gas heater

- Heating jacket

- Heating cartridge

- H-Bus loop

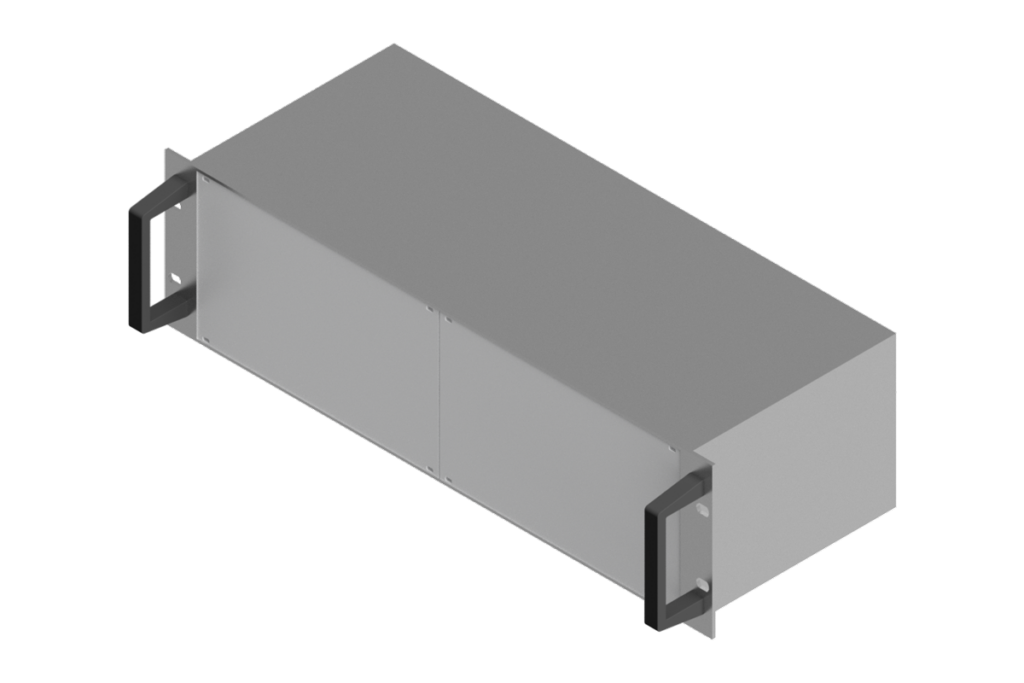

Rack insert

The 19″ rack insert allows installation of two HCC controllers or one HCC controller with one PUR 250 or CBR 200.

TPM 200 / TPM 210

Using transducer modules TPM 200 / TPM 210, the HCC controller can be expanded by adding pressure gauge heads and temperature sensors.

- Two temperature sensors (TPM 200)

- Two temperature sensors and a gauge head (TPM 210)

- HSR-Bus loop

PWF 200

The PWF 200 is a signal converter that connects the Sumitomo helium compressors F-70 and F-20 to the HCC controller.

- D-Sub connector

- HSR-Bus loop