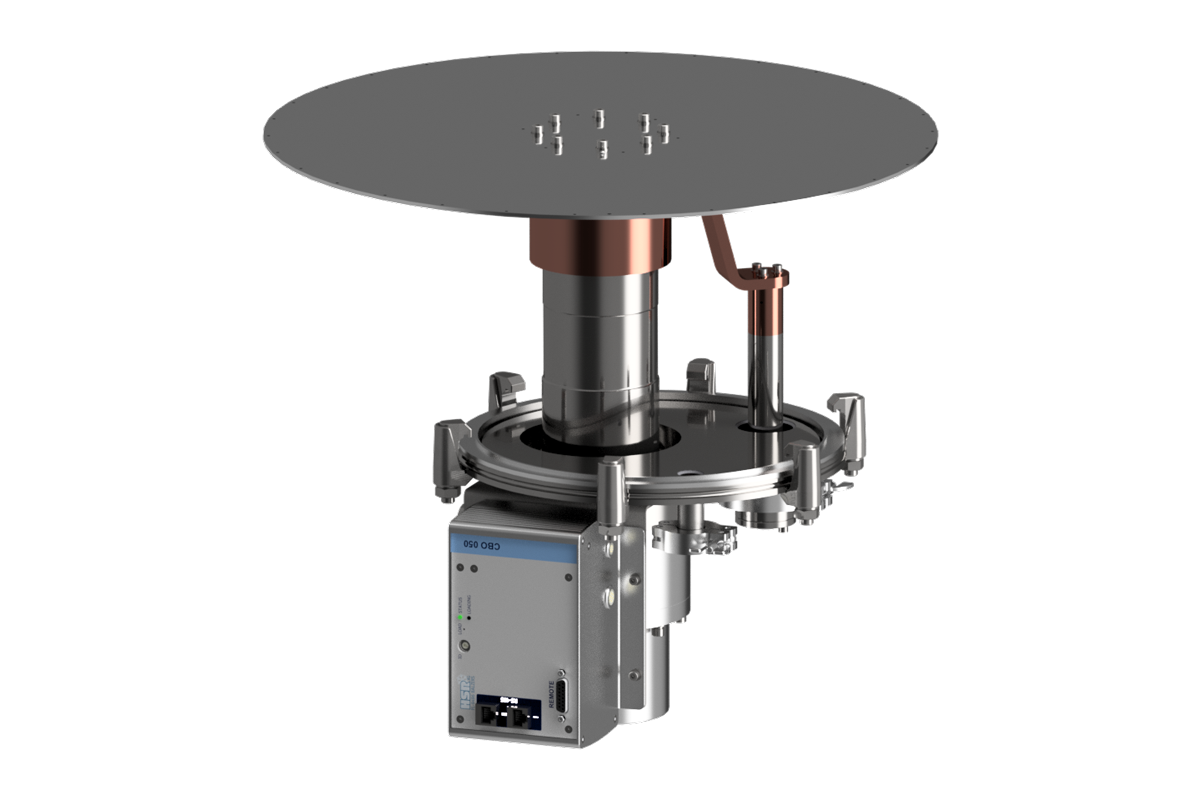

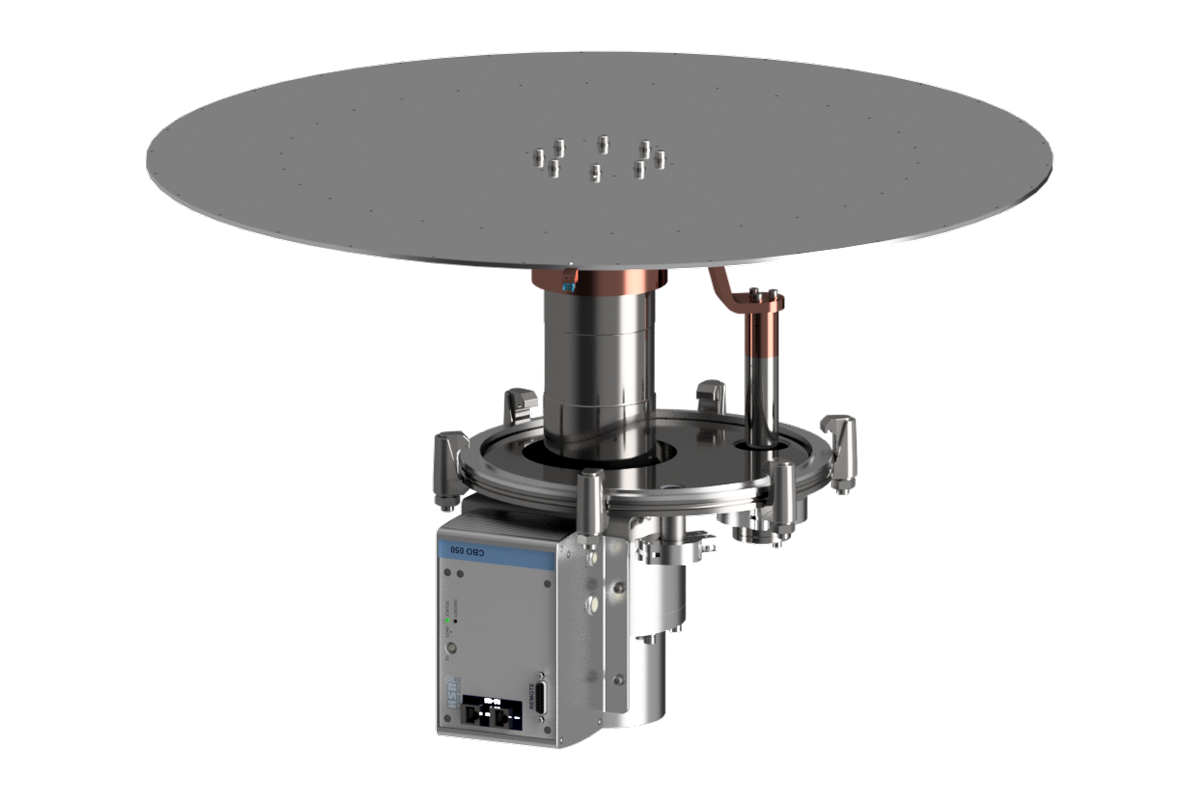

Standard HSR SINCO pumps consist of a cooling head, a heating system, and a condensation plate. In contrast to the VELCO pump, the SINCO is designed to pump only a defined gas. The advantage is that increasing the pumping speed for a specific gas in an existing cryopump is relatively cost-effective. The SINCO does not have its own housing. Consequently, the condensation plate extends directly into the vacuum chamber. HSR can also provide suitable housing if separate regeneration without purging of the vacuum chamber is required.

The fact that the condensation plate can bind gas on both sides enables high gas capacities and makes HSR SINCO pumps stand out in the market. By choosing the diameter of the condensation plate, the pump can be optimized either for capacity or for pumping speed.

HSR controllers are equipped for connecting up to 8 SINCO pumps. They can started or regenerated by a single controller. The 8 corresponding helium compressors are integrated in this control chain. The customer only requires one interface (RS-232 or Ethernet) to operate 8 pumps.

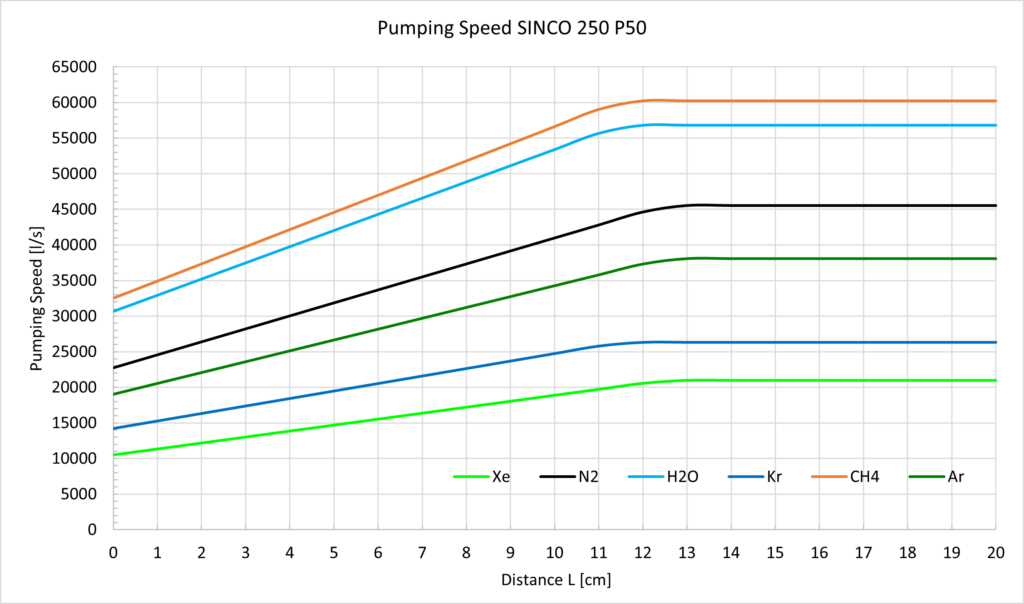

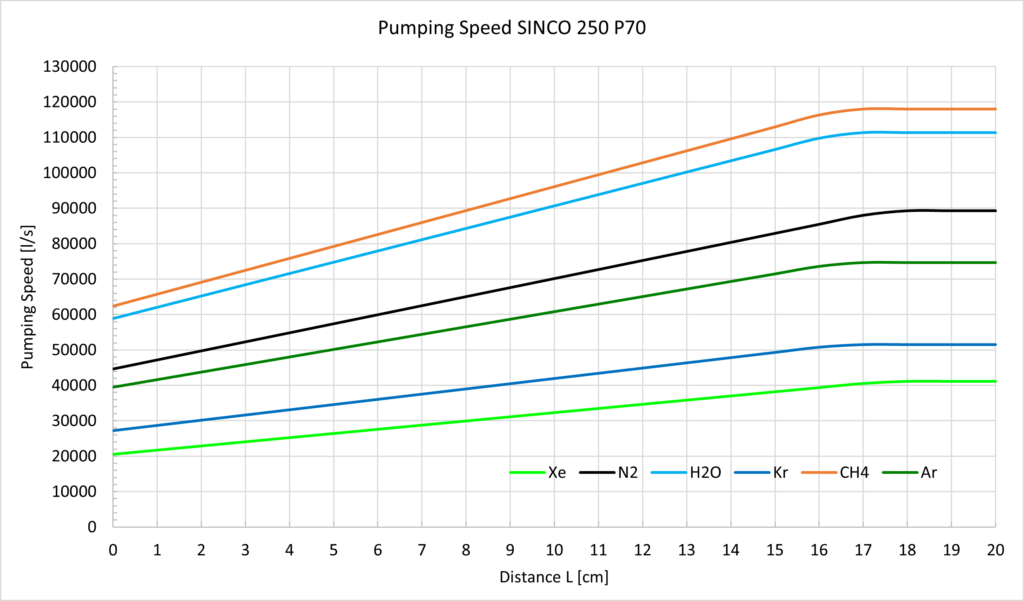

| Designation | SINCO 250 P50 | SINCO 250 P70 | |

|---|---|---|---|

| Plate diameter [mm] | 500 | 700 | |

| Connection flange, chamber | DN250 ISO-K | DN250 ISO-K | |

| Connection flanges, accessories | DN40 ISO-KF | DN40 ISO-KF | |

| DN16 ISO-KF | DN16 ISO-KF | ||

| Pumping speed dependent on L (distance plate to chamber wall) | see graph | see graph | |

| Capacity [barl] at L=10cm | |||

| Xenon @ 200 sccm | > 740 | ||

| Xenon @ 600 sccm | > 570 | ||

| Xenon @ 1200 sccm | 3’000 | > 300 | |

| Maximum pressure [mbar] | 1×10⁻³ | 1×10⁻³ | |

| Cooldown time [min] | 70 | 120 | |

| Warmup time [min] | |||

| with heating (30-273K) | 140 | 230 | |

| without heating (30-273K) | 660 | 820 | |

| Weight [kg] | 34 | 37 | |

| Mounting position | any | any | |